Processing and handling up from Ø4mm to Ø80mm metal pipes as custom

The production at FELSAN includes a wide variety of transformations on piping and profiles to offer a totally finished product, using the most advanced technology. Control, traceability, quality, subcontrators and logistic is monitorized by our network.

A. The most out-standing characteristics of the production system are:

A. The most out-standing characteristics of the production system are:

- Totally automated cutting process of pipe or profile.

- Bending with latest generation numerical control systems (CNC – DNC).

- System of interior piping cleaning, “Jet cleaner” system.

- Fully Finished product delivered with end protection.

- All types of formations (flanging, countersinking, punching, swaging, etc.)

- TIG, MAG, MIG, brazing, spot welding systems, etc.

- Assembly and Incorporation of connectors, sealing rings, etc.

- Individual identification with part number by micro-percussion.

- Design and manufacture of tools, and mechanical, hydraulic and pneumatic equipments.

- Own R&D department.

B. The most commonly used raw materials are:

- Cold-drawn seamless steel EN-10305-1, EN-10305-4 / DIN2391).

- Cold-drawn welded steel (EN-10305-2 / DIN2393 y EN-10305-3 / DIN2394).

- Copper.

- Aluminium (3103, 6063, etc.).

- Stainless steel (AISI-304, AISI-316, AISI-321, etc.).

- Brass and other special materials (titanium, alloys, etc.).

- Rectangular and Square Electric Welded Precision Steel Tubes (EN-10305-5 / DIN 2395).

C. The most common surface coatings are:

C. The most common surface coatings are:

- Zinc plating (hexavalent chromium free coating).

- Geomet.

- Nickel-zinc.

- Galvanised.

- Cataphoresis.

- Phosphating.

- Poliéster paint.

- Epoxy paint.

D. Most common application in the automotive sector:

D. Most common application in the automotive sector:

- Brake circuits.

- Gasoil circuits in diesel engines.

- Combustible Gas conduits (urban buses).

- Air conditioning and heating circuits.

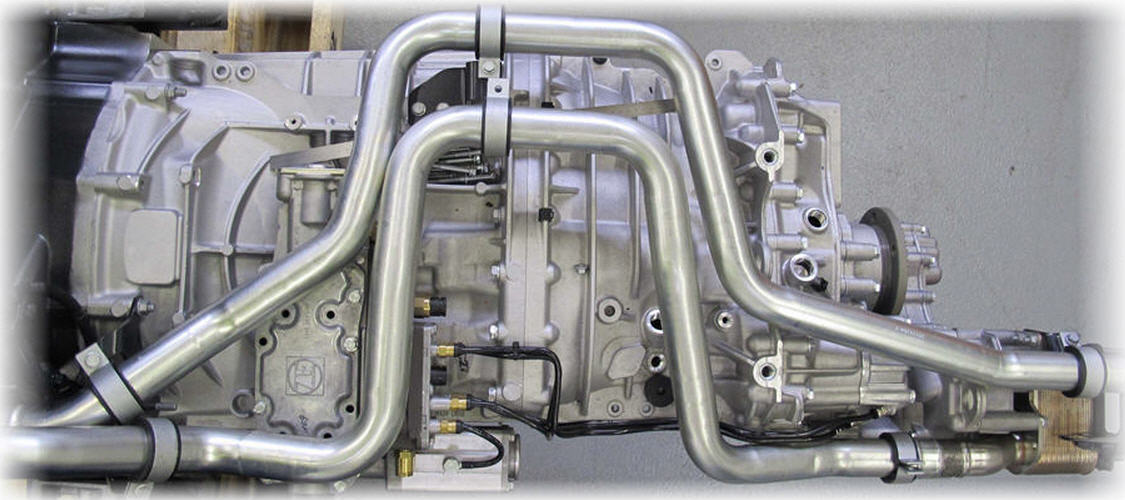

- Engine cooling circuits and INTARDER cooling (Ø50 / Ø60 / Ø70 mm).

- Hydraulic steering, elevation circuits, etc.

- Handles.

- Body cars, truck, bus.

- Etc.